- INDUSTRY 4.0

- PROFESSIONAL SLICERS

- VENTILATION

- BAR FURNITURE

- Back counters for coffee machines

- Bar counters

- Beer counters

- Bread display counters

- Built-in bar counters

- Built-in sinks

- Cocktail stations

- Ice cream counters

- Multipurpose counters

- Neutral back counters

- Pizza display counters

- Refrigerated back counters

- Snack display counters

- Stainless steel doors and drawers

- Start Up Line paneled bar counters

- Tobacco - football pool counters

- STEEL FURNITURE

- STAINLESS STEEL FURNITURE 430

- FURNITURE COMPLETE KITS

- BAR EQUIPMENT

- Blenders

- Centrifugal

- Citrus Juicers

- Coffee machines

- Crepe machine

- Displays - Snack display

- Doser Coffee Grinder

- Egg cooker

- Electric Hotplates

- Freeze glasses

- Fry top snack

- Gas plates

- Hot drinks dispenser

- Hot-dog

- Ice crushers

- Juice extractors

- Milk frother

- Pacojet

- Pancake machines

- Sauce dispenser

- Single juice dispenser

- Snack bar pasta cookers

- Toasters

- waffles makers

- Warming Plate

- Wine dispenser by the glass

- KITCHEN EQUIPMENT

- Bain maries tanks and displays

- Beer dispenser

- Can opener

- Complete workstation

- Cutter

- Cutter with cooking system

- Electric knife

- Food dehydrator - Smoker

- Fryers

- Graters

- Groups grinders

- Lava rock grills

- Mixer

- Mussel cleaners

- Onion peelers

- Pacojet / Emulsifiers

- Passatrici - Stoning machines

- Plate warmers

- Potato peeler

- Professional air fryers

- Rice cooker

- Salamanders

- Sauce dispensers

- Snack hobs

- Soup Bowls

- Thermal blenders

- Tigella maker

- Truffle wash

- Vegatable cleaner

- Vegetable Slicers

- FAST FOOD EQUIPMENT

- Bain-Marie For Sauce

- Bain-marie for sausage

- Butter spreader

- Cheese raclette

- Fast food pasta cooker

- Frytop with toaster

- Hamburger showcase

- Heated cutting station

- Heated funnel with piston

- Hot counter for chips

- Hot dog

- Multi snack trolley

- Pump Dispenser

- Storage and maintenance cabinet

- Support for containers

- Toaster

- Topping Warmer

- Warming drawer

- Workstation for crepes

- ICE CREAM PARLOR EQUIPMENT

- Ageing vats

- Batch freezers / Ice cream makers

- Blast chillers - freezers

- Containers - Ice cream various accessories

- Cream cookers

- Cream whippers

- Ice cream display counters

- Ice cream fridges

- Ice cream presses

- Ice cream sandwich maker

- Pacojet / Emulsifiers

- Pasteurizers

- Patisserie - ice cream displays

- Semifinished Ice cream display counters

- Soft serve ice cream machines

- BUTCHER EQUIPMENT

- Bagging machines

- Bone bandsaws

- Butcher Display counter

- Butcher hooks

- Butcher trolleys

- Chopping blocks

- Chopping boards

- Combi meat mincer - grater

- Curing chambers

- Exhibition floor lamp

- Gloves - Stainless steel apron

- Knife Sharpner

- Manual Hamburger Maker

- Meat cutting displays

- Meat mincers

- Meat mixer

- Meat refrigerators

- Meat Showcases

- Refrigerated meat mincer

- Sterilizers

- Tenderizers

- BAKERY EQUIPMENTS

- Bakery - pastry ovens

- Bread counters

- Bread displays - bread back counters

- Bread displays counters

- Bread dough moulders

- Bread grinders

- Bread grinders

- Bread kneader

- Bread ovens

- Breadstick makers

- Flour sieve

- Pasta and pizza dough dividers - rounders

- Retarder proofer rooms

- Retarder proofers

- Self service bakery displays

- Sourdough fermentors

- Tagliafrese

- Taralli heaters

- Water chillers

- PASTRY EQUIPMENT

- Biscuit machines

- Blast chillers - freezers

- Chocolate fountains

- Chocolate melter

- Chocolate pourers and temperers

- Chocolate spray

- Chocolate tables

- Dosing - Filling Machines

- Eggs beats

- Glazing machines

- Kurtoskalacs

- Pastry and Ice Cream display counters

- Pastry counter

- Pastry display counters

- Pastry dough sheeters

- Pastry fryers

- Pastry ovens

- Planetary mixers

- Praline mixers

- Proofers

- Refrigerated griddle

- Refrigerated patisserie tables

- Slicers

- Sourdough fermentors

- Sugar grinder

- Sugar lamps

- Tartellette machines

- Waffle makers

- PIZZA EQUIPMENT

- FOOD BANKS E MULTIDECK CHILLERS

- CHECKOUT COUNTERS

- SCALES

- TROLLEYS E ACCESSORIES

- ISOTHERMAL CONTAINERS

- CONTAINERS - TRAYS - ACCESSORIES

- LOW TEMPERATURE COOKING

- PROFESSIONAL COOKING

- ETHNIC KITCHENS

- PIADINA COOKERS

- PROTECTIVE EQUIPMENT E HYGIENE

- DROP-IN UNITS

- BUFFET AND REFRIGERATED FURNITURE

- FRUIT STANDS

- WINE DISPLAYS

- ICE MACHINES

- OVENS E PROOFERS

- PHARMACY FRIDGES

- ROTISSERIE E KEBAB

- SLUSH MACHINES E COOLERS

- PLANETARY MIXERS

- LAUNDRY

- WASHING EQUIPMENT

- PASTA MANUFACTURING

- PROFESSIONAL REFRIGERATION

- Back counters

- Beer refrigerated boxes

- Blast chillers

- Bottle coolers

- Circular refrigerators

- Cold rooms

- Combined Fridges

- Countertop - undercounter beverage dispensers

- Freezers - chillers pit

- Mini-bar

- Refrigerated snack display

- Refrigerated Tables

- Refrigerated/hot deli wall units and back counters

- Removable refrigerated cabinets

- Retarder-proofing cabinets and tables

- Upright fridge with glass door

- Upright fridges with blind door

- LUNA PARK LINE

- SERVICE FURNITURE

- RESTAURANTS E BUFFET

- WASTE DISPOSAL

- MANUAL SERIES E VARIOUS

- Sterilizers

- PACKAGING MACHINES

- "Outdoor" furnishing accessories

- FORNITURE ALBERGHIERE

- FISH LINE

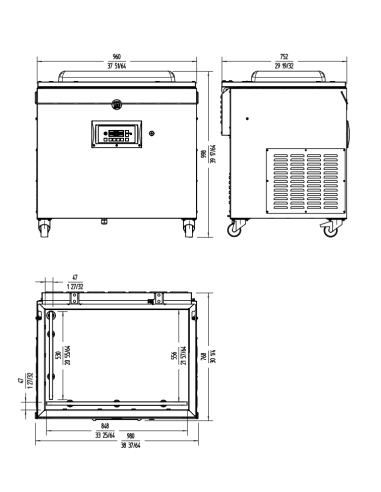

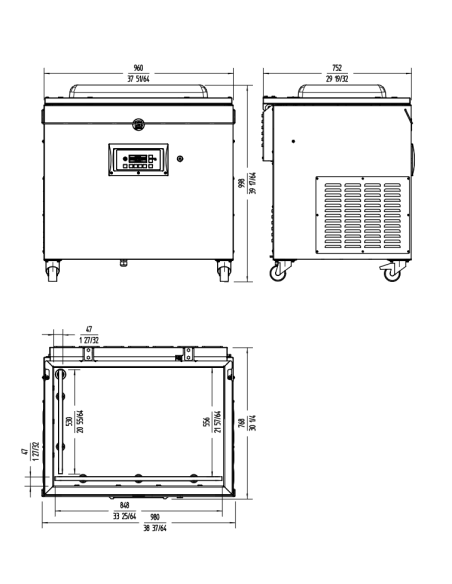

Vacuum packaging machine with double sealing bar cm 53 + 84.8 - Pump Busch 100 m3/h - cm 96 x 75,7 x 99,8 h

Vacuum packaging machine - Range'Sensor'- Series 800 - ModelSE-810 - Pump capacity Busch 100 m3/h - Two welding bars length cm 530+848 - Dust model - External dimensions cm 96 x 75,7 x 99,8 h

Options

+ ACCESSORIES

Bag cutting kit - Welding + cutting 530mm - SE / SU 800

|

Bag cutting kit - Sawing+cut 530mm - SE/OUT OF 800 |

|

Bag cutting kit - Welding + cutting 848mm - SE / SU 800

|

Bag cutting kit - Sawing+cut 848mm - SE/OUT OF 800 |

|

'Vac-Norm' external vacuum kit - Tube length 1.5 m - (model on feet)

|

Exterior vacuum kit ''Vac-Norm'' - Pipe length 1.5 m - (mod. on feet) |

|

Smooth bags for vacuum machines - Bags 180x300 mm - 80 ° C - (pack 100 units)

|

Smooth bags for vacuum machines - Bags 180x300 mm - For storage and cooking up to 80°C - (pack 100 units ) |

|

Smooth bags for vacuum machines - Envelopes 300x400 mm - 80 ° C - (pack 100 units) |

Smooth bags for vacuum machines - Bags 300x400 mm - For storage and cooking up to 80°C - (pack 100 units ) |

|

Smooth bags for vacuum machines - Bags 350x550 mm - For storage and cooking up to 80 ° C - (pack 100 units) |

Smooth bags for vacuum machines - Bags 350x550 mm - For storage and cooking up to 80°C - (pack 100 units ) |

|

Smooth bags for vacuum machines - Bags 180x300 mm - For storage and cooking up to 120 ° C - (pack 100 units)

|

Smooth bags for vacuum machines - Bags 180x300 mm - For storage and cooking up to 120°C - (pack 100 units ) |

|

Smooth bags for vacuum machines - Envelopes 300x400 mm - For storage and cooking up to 120 ° C - (pack 100 units) |

Smooth bags for vacuum machines - Bags 300x400 mm - For storage and cooking up to 120°C - (pack 100 units ) |

|

Smooth bags for vacuum machines - Bags 350x550 mm - For storage and cooking up to 120 ° C - (pack 100 units)

|

Smooth bags for vacuum machines - Bags 350x550 mm - For storage and cooking up to 120°C - (pack 100 units ) |

|

Supports for packaging liquids - For vacuum packaging machines - SE / SU 800 - Adjustable stop

|

Liquid packaging supports - For vacuum packaging machines - SE/SU 800 - Adjustable lock |

|

Vac-norm container 1/1 100 - Made of stainless steel

|

Vac-norm container 1/1 100 - Made of stainless steel |

|

Vac-norm container 1/1 150 - Made of stainless steel

|

Vac-norm container 1/1 150 - Made of stainless steel |

|

Vac-norm container 1/2 100 - Made of stainless steel

|

Vac-norm container 1/2 100 - Made of stainless steel |

|

Vac-norm container 1/2 150 - Made of stainless steel

|

Vac-norm container 1/2 150 - Made of stainless steel |

|

Vac-norm container 1/3 100 - Made of stainless steel

|

Vac-norm container 1/3 100 - Made of stainless steel |

|

Vac-norm container 1/3 150 - Made of stainless steel

|

Vac-norm container 1/3 150 - Made of stainless steel |

|

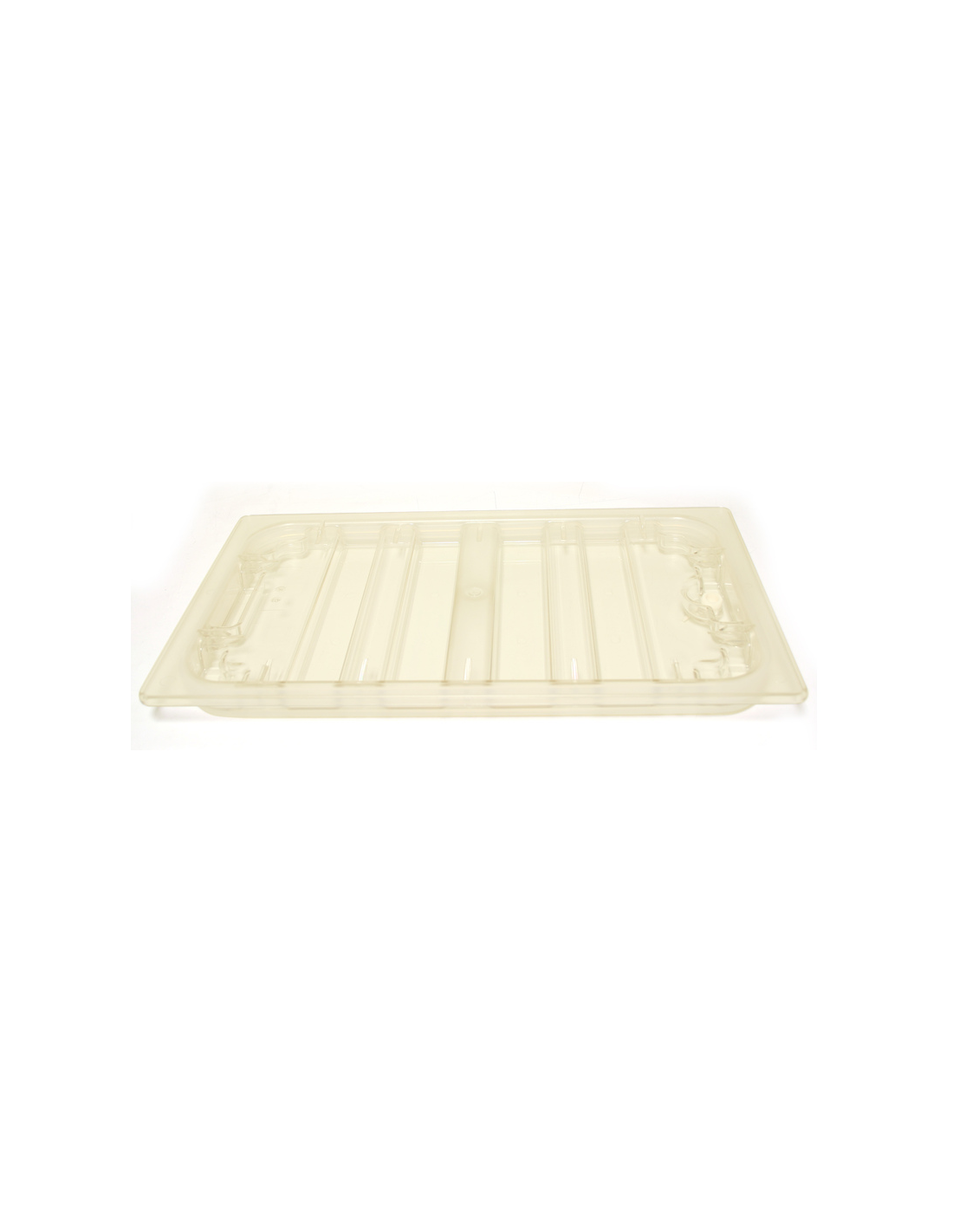

Vac-norm lid 1/1 |

Cover vac-norm 1/1 |

|

Vac-norm lid 1/2 |

Cover vac-norm 1/2 |

|

Vac-norm cover 1/3 |

Cover vac-norm 1/3 |

|

Seal vac-norm 1/1 |

Coptic gasket vac-norm 1/1 |

|

Seal vac-norm 1/2 |

Coptic gasket vac-norm 1/2 |

|

Seal vac-norm 1/3 |

Coptic gasket vac-norm 1/3 |

|

Cop vac-norm valve |

Valve cop vac-norm |

SELLA PERSONAL CREDIT

SHIPMENTS AND DELIVERIES

Couriers deliver to street level and porterage service is excluded. When ordering, the customer is required to inform if delivery is to be made to an inconvenient area. Disturbed areas are all those places that due to distance or conformation of the territory are difficult to reach, ( e.g. islands, LTZ, historical centers, alleys, etc..) To deliver to these destinations, couriers require longer delivery times and the payment of an extra commission.

The goods will be shipped to the address provided during the order process. If it is to be delivered to a different address, it is the customer's responsibility to notify us at the time of ordering. If, after the shipment has been handled, the customer decides to change the destination address, the goods go into storage, resulting in charges for opening the file and for shipping

Professional machinery often comes without the socket for several technical and regulatory reasons:

Standardization and compatibility: Professional machinery is used in different parts of the world, where socket standards and electrical voltages vary. Providing the cord without a socket allows users to adapt the machinery to the standards of their country or work environment.

Installation customization: Professional machinery is often installed by qualified technicians who choose the type of socket or connection best suited to the customer's needs, such as direct connections to the electrical system or specific industrial sockets.

Safety regulations: In some professional settings, regulations require that machinery be connected directly to the electrical system through an earth leakage circuit breaker or fixed connection, rather than through a standard outlet. This reduces the risk of overloading or electrical failure.

Versatility of use: Providing the cable without a socket allows greater flexibility in configuration, preventing the manufacturer from having to manage product variants with specific sockets for each market.

Cost and waste reduction: Not including the socket reduces production costs and avoids waste in case the end user needs a different type of connection.

This practice is common for equipment requiring technical installation or operating in professional environments with specific requirements.

TERMS OF PAYMENT: You will be able to pay for the products ordered on our portal using the following payment methods

_______________________________

1) PAYPAL

1) PAYPAL

D.L.Service Div. E-Commerce Srl provides all the security and speed of payment through Paypal, a secure means of sending money, because it is possible to pay without sharing credit card data.

1) CREDIT OR PAY DEBT CARD IN 2.3.4 INSTALLMENTS

1) CREDIT OR PAY DEBT CARD IN 2.3.4 INSTALLMENTS

Alma is available for purchases suitable value between € 50.00 and € 2,000.00. It can be paid in 2.3.4 comfortable installments. Payment allowed also in some European countries.

2) CREDIT CARD

2) CREDIT CARD

By choosing payment by credit card you will be automatically directed to the website of the bank that will handle the transaction. The accepted credit cards are all those that rely on the Visa, MasterCard, American Express, CartaSi, Maestro circuit. The security of the transaction is guaranteed by a data encryption system that uses SSL (Secure Socket Layer) certificates

3) 30% ADVANCE PAYMENT WITH 70% BALANCE WHEN GOODS READY

3) 30% ADVANCE PAYMENT WITH 70% BALANCE WHEN GOODS READY

By choosing this payment method you will have to pay 30% of the total order and the remaining 70% when the goods are ready for shipment. In this case, the customer will be notified two days before shipment in order to issue the balance transfer.

4) ADVANCE BANK TRANSFER

4) ADVANCE BANK TRANSFER

If you prefer to pay by bank transfer, you must send the accounting copy via email: info@ristorazione-refrigerazione.it or via WhatApp to n. +39 389 7940545. The purpose of the transfer must include the order number

Production times can vary from 3 to 15 days. The "Prompt Delivery" sticker is present on thousands of products. For all other products you can request availability by contacting our Customer Care on +39 0824 1816643, sending a WhatsApp message to no. +39 389 7940545 or send an email to info@ristorazione-refrigerazione.it

| Vacuum packaging machine | Model SE810 |

| Dimensions | cm 96 x 75,7 x 99,8 h |

| Packaging dimensions | cm 84 x 106 x 120h |

| Net / gross | Kg 250-259 |

| Norma | CE |

| Warranty | 12 months |

| TECHNICAL DATA | |

|---|---|

| Pump capacity | 10 m3/h |

| Length of welding bar | 530 mm + 848 mm |

| Power Total | 2200 W |

| Vacuum pressure (maximum) | 0.5 mbar |

| Power supply | 400 V--- V / 50-60 Hz / 3N ~ (9 A) |

| Pump capacity (60 Hz) | 120 m3/h |

| GENERAL FEATURES | |

|---|---|

| Increases the retention time of raw or cooked foods without weight loss. | |

| Designed for the packaging of raw or seasoned foods, for the packaging of traditionally cooked products, for vacuum cooking, for the packaging of products to be frozen subsequently, for non-food or "no-food" use | |

| The digital control panel is equipped with display indicating the exact vacuum percentage | |

| High precision sensor controlled vacuum: precise and consistent results always, regardless of the quantity to be packaged | |

| “Pause” button for marinating food in the room | |

| Safety in liquid packaging thanks to sensor control | |

| Double sealing | |

| Cable-free sealing bar: barrier-free tub, which simplifies cleaning and maintenance | |

| Container sealing program by setting a vacuum less than vacuum program | |

| Pulse-controlled decompression prevents product damage and container breakage | |

| Vac-Norm ready: prepared for external vacuum in "Vac-Norm" containers controlled by sensor. | |

| Automatic decompression to recover the pipe at the end of the cycle | |

| High Quality Stainless Steel Structure | |

| Stainless steel tank, internally coated and without edges, with rounded edges | |

| Shocked cover of transparent polycarbonate, very durable | |

| Dry-oil program for drying the pump, prolonging the useful life of the pump | |

| Time counter for oil change | |

| Safety system with maximum operating time protection or vacuum anomalous | |

| Model approved by NSF: safety and hygiene guarantee | |

| Sealing bars with curved resistors that allow to eliminate product residues and guarantee sealing. |

- SEALING BAR

- cm 53+84,8

16 other products in the same category:

Vacuum Bell - Welding Bar 30 cm - cm 39.5 x 49 x 37.4 h

Vacuum Bell - Cart - Welding bars 2 x 470 mm + 920 mm - cm 106 x 68.7 x 91h

Vacuum bell - Welding bar mm 305 - Cm 41 x 48 x 100 h

Vacuum bell - Welding bar 510 mm - cm 61.2 x 66.7 x 37h

Vacuum Bell - Cart - Welding bar 920 mm - cm 106 x 68.7 x 91h

Vacuum packaging machine with double sealing bar cm 84.8 + 84.8 - Pump Busch 63 m3/h -...

Vacuum Bell - Cart - Welding bar 680 mm + 500 mm - cm 80 x 69 x 91h

Vacuum Bell - Cart - Welding bars 2 x 650 mm + 2 x 540 mm - cm 80 x 69 x 91h

Vacuum Bell - Cart - Welding bar from 680 mm x 2 - cm 80 x 69 x 93h

Bell vacuum - Cart - Welding bar 540 mm x 2 - cm 106 x 68.7 x 91h

Vacuum bell - Barre 2 x 920 mm + 2 x 460 mm - cm 106 x 68.7 x 91h

Vacuum bell - Welding bar: 320 mm - cm 39 x 53 x 32h

Vacuum bell - Welding bar 510 mm x 2 - cm 61.2 x 66.7 x 37h

Vacuum bell - Welding bar mm 505 - Cm 61 x 68 x 100 h

Home

- PROFESSIONAL SLICERS

- BAR FURNITURE

- Refrigerated back counters

- Back counters for coffee machines

- Neutral back counters

- Multipurpose counters

- Cocktail stations

- Bar counters

- Beer counters

- Tobacco - football pool counters

- Built-in bar counters

- Stainless steel doors and drawers

- Snack display counters

- Bread display counters

- Pizza display counters

- Start Up Line paneled bar counters

- Ice cream counters

- Built-in sinks

- STEEL FURNITURE

- STAINLESS STEEL FURNITURE 430

- BAR-

- FURNITURE COMPLETE KITS

- VENTILATION

- ICE CREAM EQUIPMENT

- BAR EQUIPMENT

- Sauce dispenser

- Pacojet

- Pancake machines

- Toasters

- Hot-dog

- Crepe machine

- Displays - Snack display

- Electric Hotplates

- Fry top snack

- Blenders

- Ice crushers

- Centrifugal

- Citrus Juicers

- Warming Plate

- Hot drinks dispenser

- Doser Coffee Grinder

- Gas plates

- Egg cooker

- Snack bar pasta cookers

- Juice extractors

- Coffee machines

- waffles makers

- Single juice dispenser

- Freeze glasses

- Wine dispenser by the glass

- Milk frother

- KITCHEN EQUIPMENT

- Truffle wash

- Beer dispenser

- Passatrici - Stoning machines

- Mixer

- Groups grinders

- Fryers

- Mussel cleaners

- Bain maries tanks and displays

- Onion peelers

- Salamanders

- Plate warmers

- Rice cooker

- Complete workstation

- Pacojet / Emulsifiers

- Vegatable cleaner

- Lava rock grills

- Thermal blenders

- Food dehydrator - Smoker

- Soup Bowls

- Snack hobs

- Cutter with cooking system

- Tigella maker

- Sauce dispensers

- Can opener

- Electric knife

- Professional air fryers

- Potato peeler

- Cutter

- Graters

- Vegetable Slicers

- ICE CREAM PARLOR EQUIPMENT

- Blast chillers - freezers

- Ice cream display counters

- Cream cookers

- Batch freezers / Ice cream makers

- Soft serve ice cream machines

- Cream whippers

- Pasteurizers

- Ice cream presses

- Patisserie - ice cream displays

- Semifinished Ice cream display counters

- Ageing vats

- Ice cream fridges

- Containers - Ice cream various accessories

- Ice cream sandwich maker

- Pacojet / Emulsifiers

- BUTCHER EQUIPMENT

- Sterilizers

- Meat Showcases

- Meat mincers

- Bone bandsaws

- Chopping blocks

- Tenderizers

- Meat mixer

- Combi meat mincer - grater

- Refrigerated meat mincer

- Curing chambers

- Butcher Display counter

- Knife Sharpner

- Manual Hamburger Maker

- Chopping boards

- Gloves - Stainless steel apron

- Butcher trolleys

- Exhibition floor lamp

- Butcher hooks

- Meat cutting displays

- Bagging machines

- Meat refrigerators

- BAKERY EQUIPMENTS

- Bread displays counters

- Sourdough fermentors

- Bread grinders

- Retarder proofers

- Bread dough moulders

- Breadstick makers

- Taralli heaters

- Flour sieve

- Bread counters

- Tagliafrese

- Pasta and pizza dough dividers - rounders

- Bread ovens

- Bakery - pastry ovens

- Bread kneader

- Bread displays - bread back counters

- Self service bakery displays

- Retarder proofer rooms

- Water chillers

- Bread grinders

- PASTRY EQUIPMENT

- Pastry and Ice Cream display counters

- Refrigerated patisserie tables

- Waffle makers

- Proofers

- Blast chillers - freezers

- Praline mixers

- Pastry dough sheeters

- Pastry fryers

- Pastry counter

- Chocolate pourers and temperers

- Chocolate melter

- Chocolate spray

- Refrigerated griddle

- Tartellette machines

- Dosing - Filling Machines

- Chocolate fountains

- Kurtoskalacs

- Pastry ovens

- Planetary mixers

- Eggs beats

- Sugar grinder

- Pastry display counters

- Slicers

- Sourdough fermentors

- Glazing machines

- Sugar lamps

- Biscuit machines

- Chocolate tables

- PIZZA EQUIPMENT

- FOOD BANKS E MULTIDECK CHILLERS

- CHECKOUT COUNTERS

- SCALES

- TROLLEYS E ACCESSORIES

- NEUTRAL|HOT|REFRIGERATED DRAWERS

- ISOTHERMAL CONTAINERS

- CONTAINERS - TRAYS - ACCESSORIES

- LOW TEMPERATURE COOKING

- PROFESSIONAL COOKING

- ETHNIC KITCHENS

- PIADINA COOKERS

- PROTECTIVE EQUIPMENT E HYGIENE

- DROP-IN UNITS

- BUFFET AND REFRIGERATED FURNITURE

- FRUIT STANDS

- WINE DISPLAYS

- ICE MACHINES

- OVENS E PROOFERS

- PHARMACY FRIDGES

- ROTISSERIE E KEBAB

- SLUSH MACHINES E COOLERS

- PLANETARY MIXERS

- LAUNDRY

- WASHING EQUIPMENT

- PASTA MANUFACTURING

- PROFESSIONAL REFRIGERATION

- Upright fridge with glass door

- Freezers - chillers pit

- Refrigerated Tables

- Refrigerated snack display

- Mini-bar

- Upright fridges with blind door

- Combined Fridges

- Refrigerated/hot deli wall units and back counters

- Cold rooms

- Countertop - undercounter beverage dispensers

- Beer refrigerated boxes

- Blast chillers

- Bottle coolers

- Retarder-proofing cabinets and tables

- Back counters

- Circular refrigerators

- Removable refrigerated cabinets

- FISH LINE

- LUNA PARK LINE

- SERVICE FURNITURE

- INDUSTRY 4.0

- RESTAURANTS E BUFFET

- WASTE DISPOSAL

- MANUAL SERIES E VARIOUS

- Sterilizers

- PACKAGING MACHINES

- "Outdoor" furnishing accessories

- FAST FOOD EQUIPMENT

- Hot dog

- Bain-Marie For Sauce

- Bain-marie for sausage

- Hamburger showcase

- Multi snack trolley

- Heated cutting station

- Topping Warmer

- Heated funnel with piston

- Frytop with toaster

- Pump Dispenser

- Workstation for crepes

- Hot counter for chips

- Cheese raclette

- Warming drawer

- Toaster

- Butter spreader

- Fast food pasta cooker

- Storage and maintenance cabinet

- Support for containers

.png)