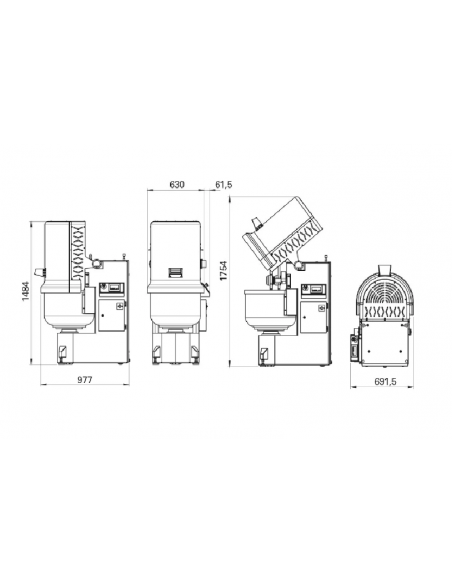

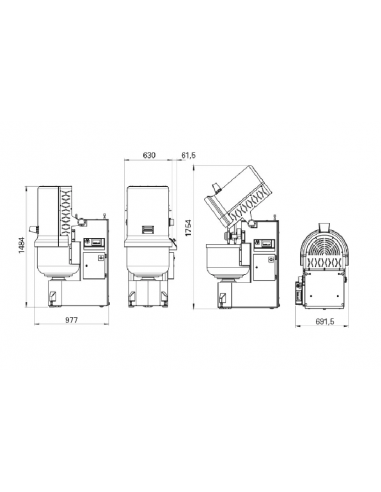

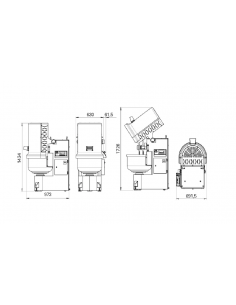

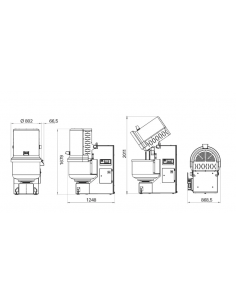

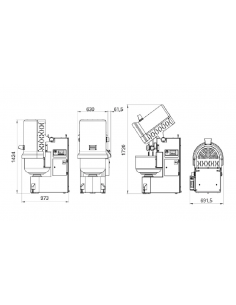

Kneading arms - Capacity kg 5/64 - cm 69.15 x 97.7 x 148.4 (175.4)h

Diving arms kneader - Model ITWIN65 - Mixing capacity (min/max) kg 5/64 - flour capacity (min/max) kg 3/40 - Water capacity (min/max) lt 2/24 - Bath volume lt 90 - Size cm 69.15 x 97.7 x 148.4 (175.4)h

| PRODUCT INFORMATION | |

|---|---|

| Diving arms kneader | ITWIN65 |

| Dimensions | cm 69.15 x 97.7 x 148.4 (175.4)h |

| Net weight | Kg 330 |

| Warranty | 12 months |

| Norma | CE |

| TECHNICAL DATA | |

|---|---|

| Capacity of dough | (min/max) kg 5/64 |

| Flour capacity | (min/max) kg 3/40 |

| Water capacity | (min/max) |

| Tank volume | lt 90 |

| Water / flour (min) | 60 % |

| Speed of arms | 1st/2nd speed MAN/PRO bpm 40/60 - inverter INV/TOUCH bpm from 25 to 75 |

| Tank speed | 1st/2nd speed MAN/PRO rpm 8/12- inverter INV/ TOUCH rpm from 5 to 15 |

| Size | cm 55 x 39 |

| Power engine | 1st/2nd speed MAN /PRO Kw 1.5/2.2 - inverter INV /TOUCH Kw 2.2 |

| Power supply | MAN - PRO - INV - TOUCH V 400/3/50-60 or V 230/3/50-60 or INV model - TOUCH V 230/1/50-60 |

| GENERAL FEATURES | |

|---|---|

| Electric motor brake. | |

| Ability of dough calculated with 60% hydration. The maximum capacity can vary according to the ingredients. | |

| Painted steel frame with certified non-toxic paints for food use | |

| Built in stainless steel of considerable thickness with reinforcement at the base | |

| The arms are made of stainless steel of considerable thickness and mounted on self-lubricated ball bearings. The left arm is equipped with a “loop back” to take the dough, while the right arm is designed to spread the dough | |

| Gears made of spheroid cast iron melt immersed in oil bath to ensure quietness and durability | |

| Rotating hydraulic decelerator that increases the degree of safety of our machines when the tank protection is lifted or lowered | |

| Motor available in three-phase version 2 speeds and in three-phase/monofase version with variable speed (INVERTER) | |

| All machines are supplied standard with connection in 400 Volt 50/60 Hz 3 stages. On request, you can do with different tensions | |

| Motion transmission with pulleys and trapezoidal straps to ensure maximum silence and reliability. The tank is connected to a gear motor | |

| Anti-shock plexiglass refill. Respect all hygiene and health regulations | |

| Equipped with wheels for handling and two feet stabilizers, to maintain a hygienic level in your laboratory. Adjustable front foot support | |

| Fast hook/unlock system half locks reducing cleaning and maintenance times |

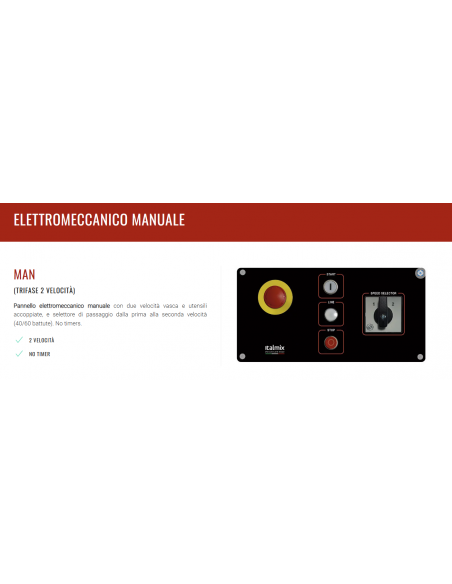

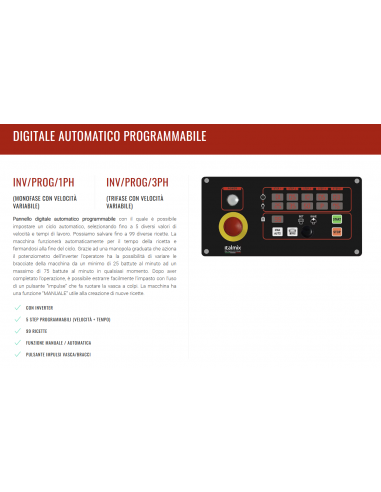

| TYPE OF PANEL | |

|---|---|

|

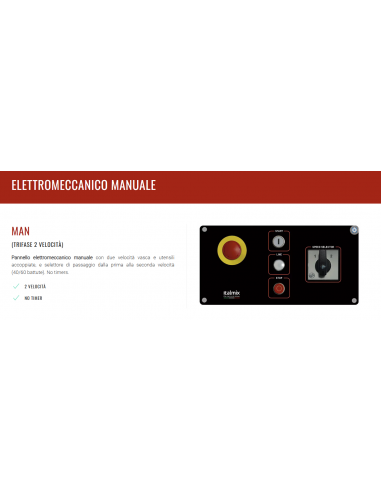

MANUAL ELECTROMECANIC (MAN) Three-phase 2 speeds. Manual electromechanical panel with two tank speeds and coupled tools and switch from first to second speed (40/60 lines). No timers. |

|

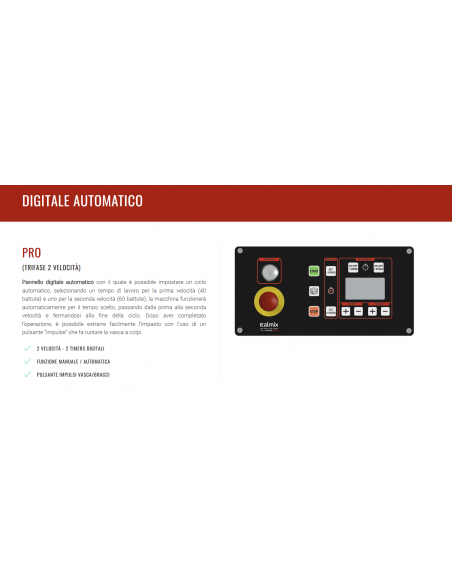

|

AUTOMATIC DEGITAL (PRO) 2 speeds - 2 digital timers- MANUAL function / AUTOMATIC- Bath/braces pulse button. Automatic digital panel with which you can set an automatic cycle, selecting a working time for the first speed (40 beats) and one for the second speed (60 beats), the machine will automatically work for the chosen time, from the first to the second speed and stopping at the end of the cycle. After completing the operation, you can easily extract the dough with the use of a “impulse” button that rotates the tank to hits. |

|

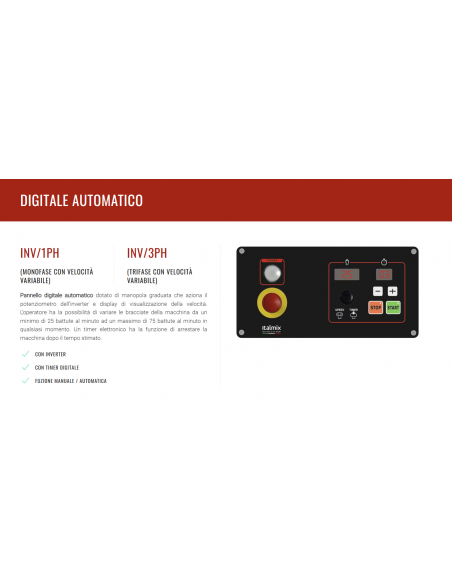

|

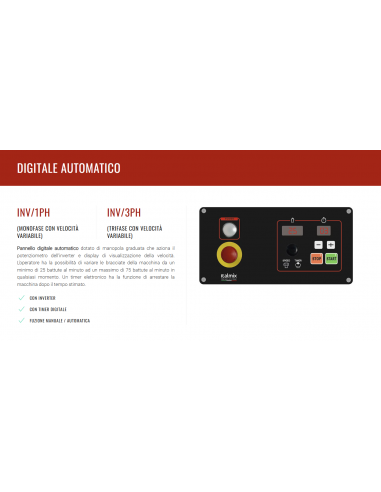

AUTOMATIC DIGITAL INV/1PH (Monophase with variable speed) or INV/3PH (Triphase with variable speed) With inverter (display speed) - With digital timer - MANUAL function / AUTOMATICAC Automatic digital panel with graduated knob that drives the inverter potentiometer and display speed. The operator has the possibility to change the machine's bracelets from a minimum of 25 jokes per minute to a maximum of 75 jokes per minute at any time. An electronic timer has the function of stopping the machine after the estimated time. |

|

|

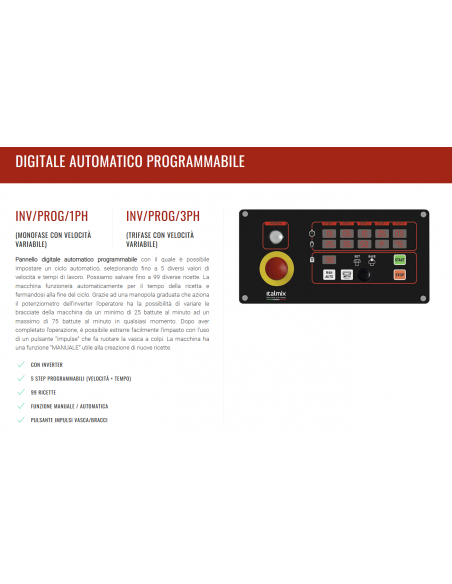

V/PROG/1PH (Monophase with variable speed) or INV/PROG/3PH (Triphase with variable speed) With inverter - 5 programmable steps (speed + time) - 99 recipes - MANUAL function / AUTOMATIC - Bath/brace pulse button Programmable digital panel with which you can set an automatic cycle, selecting up to 5 different speed values and working times. We can save up to 99 different recipes. The machine will automatically work for the time of the recipe and stopping at the end of the cycle. Thanks to a graduated knob that drives the inverter potentiometer, the operator has the possibility to change the machine's arms from a minimum of 25 jokes per minute to a maximum of 75 jokes per minute at any time. After completing the operation, you can easily extract the dough with the use of a “impulse” button that rotates the tank to hits. The machine has a “MANUAL” function useful for creating new recipes. |

|

|

TOUCH AUTOMATIC PROGRAMME TOUCH/1PH (Monophase with variable speed) or TOUCH/3PH (Triphase with variable speed) With inverter - Plc mitsubishi - SD memory for recipes - MANUAL / AUTOMATIC function - Bath/brace pulse button Automatic touch screen and PLC mitsubishi, thanks to which we can store endless recipes. The operator has the possibility to set different parameters for each recipe, such as the number of phases of dough, the speeds, times and breaks necessary for the addition of ingredients or to make the dough rest. Speeds can be set by a minimum of 25 jokes per minute to a maximum of 75 jokes per minute, and varied at any time. The machine has a “MANUAL” function useful for creating new recipes. After completing the operation, you can easily extract the dough with the use of a “impulse” button that rotates the tank to hits. Designed in compliance with INDUSTRY 4.0 technological regulations. |

- *MODEL

- *1 Velocità

- *CAPACITY KG

- *kg 60