- -8%

Roller Grinder - Length cm 120 - Ø cm 18 - cm 141 x 39.5 x 107 h

D-LLG-STI120

D-LLG-STI120

€2,543.80

€2,765.00

-8%

€2,543.80 Senza tasse

€3,103.44 Con tasse

€2,765.00 Senza tasse

Tax excluded

Shipping times: from 3 days to 15 working days

Roller ironer - Model STI120 - Automatic conca movement - Productivity kg 25 - Length cm 120 - Diameter cm 18 - Power kW 4.68 - Triphase - Dimensions cm 141 x 39.5 x 107 h

| Roller Grinder | Model STI120 |

| Product size | C 141 x 39.5 x 107 h |

| Packaging dimensions | C 152 x 53 x 131 h |

| Net weight / Lord | Kg 105/116 |

| Warranty | 12 months |

| Norma | CE |

| Origin | Italy |

| TECHNICAL DATA | |

|---|---|

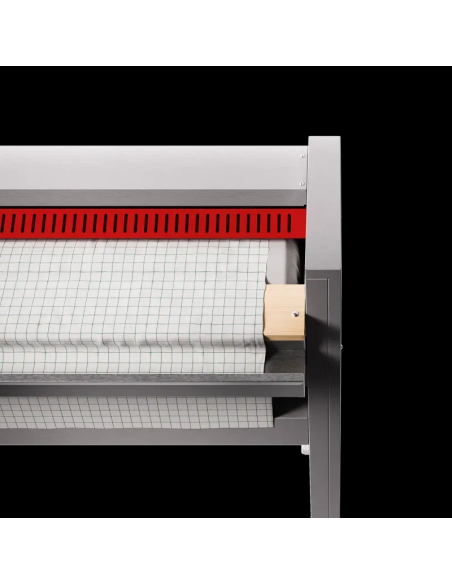

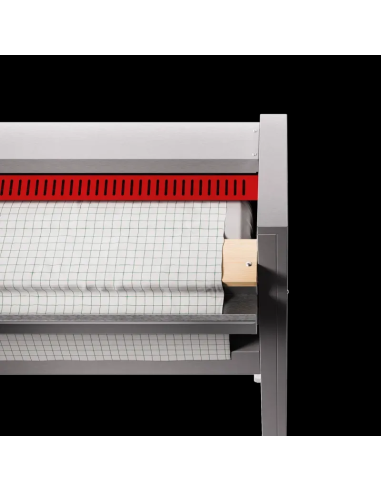

| Diameter of roller | 180 mm |

| Length of roll | mm 1200 mm |

| Productivity kg/h with UR% 10÷15% | 25 |

| Speed | mt/min 2.5 |

| External coating | Cotton cloth |

| Contact surface | 0.216 m2 |

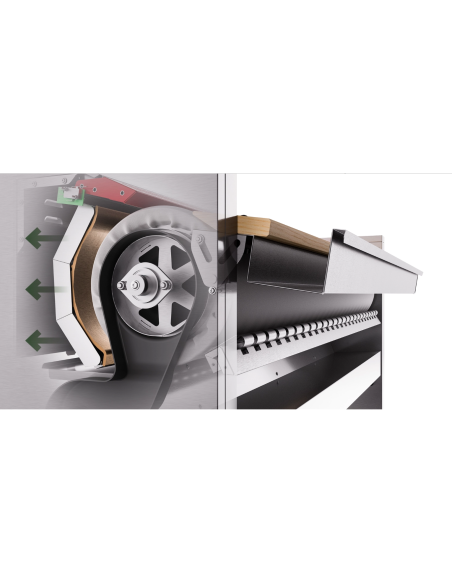

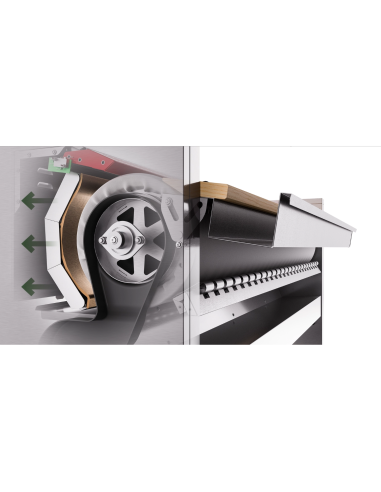

| Conca Movement | Automatic |

| ELECTRICAL DATA | |

|---|---|

| Power supply | Triphase V380-415/3/50H |

| Power thermal thermal thermal thermal | kW 4.5 |

| Power engine roller | kW 0.03 |

| Power motor conca | Kw 0.05 |

| Power total | Kw 4.68 |

| Rumours | 60 dB |

| GENERAL FEATURES | |

|---|---|

| Self-supporting structure made of grey plastic plate with small side shoulders for the advantage of the roller width useful for ironing operations | |

| Automatic conca movement through new patented system free from maintenance and self-regulating | |

| Push elements positioned behind the conca for uniformity of ironing quality throughout the roller | |

| Aluminum conca treated with deep anodising guarantee of long life and energy saving | |

| Heating elements positioned inside the aluminium rod for excellent heat transmission | |

| Thermal insulation with thick ceramic wool | |

| Roller supported by bearings and padded with triple layer of steel wool, cotton spring and outer cotton cloth | |

| Single-front use with possibility of pulling the wall-mounted ironing machine | |

| Wooden axis to facilitate the introduction of the linen with adjustable angle so as to adapt to the height of the operator | |

| Wide upper part of the roller available to the operator to achieve a particularly useful introduction band effect in the case of large garments | |

| Hand-saving device for operator protection in case of wrong maneuvers with forced air cooling system | |

| Fox electronic control with temperature control with electronic thermostat | |

| Control panel placed in such a way that you can easily manage the parameters with one finger and without moving from the workplace | |

| Safety thermostat to prevent undesirable overheaving of manual rearmament | |

| Escalator for the control of the movement of the conca (open/close) where more frequent garments of the standard are to be introduced | |

| Automatic device for removing the conca from the roller in case of lack of electricity that secures the machine and immediately allows to remove the head that was ironing |

100 Items